Recycling the electric wire can provide some benefits from financial aspects. And pliers come first to strip the wire out of the protective insulator. But when you have a frenzy in your hands, only a wire stripper can ease the job.

There’s no need to get the commercial stripping tools inside the head. You can make your own gear, thanks to some skillful DIYers. Just continue reading to explore the simplest ideas regarding DIY wire stripper implementation.

Table of Contents

1. Functional Stripping Machine

Implementing the guidelines should feel like a delicate yet enjoyable DIY project. But the approach is rather simple within your reach, in terms of resources or budget.

You just have to size up a good number of rectangular plywood or MDF boards. Following a full spray surface paint, you’re to make drilled holes for making the attachments.

Using nut & bolt connectivity, the rest is easy with joining the specified ball bearings. Final outcome is solid, elegant, functional & satisfying to strip the insulating exterior.

2. Basic Cable Wire Stripper

The video guidance reveals an amazingly visual method to craft the machine. you don’t have to create some bulky, time-consuming, precisely measured assembly.

And the raw materials should give a surprise, featuring a wooden peg, pencil sharpener, screwdriver & drill bit. The dynamics continue with on-screen steps in words to explain the action.

Although pretty basic, the tiny mechanical device can definitely serve the intended cause. Also, you’ll find some extra details to support the project right below the screen.

3. Homemade Wire Stripping Tool

Get rid of the messy pile of scrap wires for opening the workspace. Make a convenient machine to remove the exterior insulation for judging the wire’s validity. Of course, the intended tutorial lets you idealize the project right at home.

Simple facilitation skips hassling jobs like welding or some permanent connectivity. You just need to drill edged holes, place some supporting nuts & attach the shaft reinforcement.

Despite there are no defined sections, following the wordy sentences should hold the job. Included standstill images should explain the words in a better way. It’s also possible to produce the model on a smaller scale, regarding its market value.

4. Wire Stripper for Scrapping

Get your scrapping wires ready for use with the simple stripper system. Some regular household items in fresh conditions get assembled to make up the machine.

The video itself maintains a simple approach towards the viewer, skipping verbose details. You just need one razor blade with a wooden piece, connected by screws.

Following the tutorial throughout its run time should clarify the implantation. Supporting audio description should explain the ongoing process at a normal pace.

5. Recycling Copper Wire Stripper

Making the perfect mechanical equipment requires some dedication to the tutorial. You’re to achieve one homemade stripper to compete with the commercial models. The featured article provides in-depth details to implement a complex system.

Two different sections cover the entire assembly – primary base & powering motor. Of course, you can use some relevant break to follow the sequential action.

There are 10 steps in total – presenting an orderly segment for an easy understanding. And each one included depicting figures, aside from the integration of video demonstration. Comprehensive layout guide will cost your time to deliver maximum output.

6. Simplest Stripping Mechanism

The video seems more like an amateur project to strip out the copper wire. But the presentation is pretty simple with nothing but one wooden piece & an inserted screw.

Pulling the cable through the hole, keeping the screw in touch, should do the trick. Even the absolute novices can adapt the philosophy to treat the cable of any specific size.

7. Seamless Wire Stripper System

You don’t have to settle for complex mechanical gears to accomplish the target. Any passionate homeowner can address a moderate number of wires. The tutorial originates from a simple DIY video for cleaning up the mess.

The seamless project takes some mere minutes to assemble basic household pieces. But the outcome should satisfy your needs unless your load is pretty large.

Dynamic demonstration breaks down all the sequential steps at a balanced pace. Also, you’ll get a somewhat rough idea of an effective field outcome. Absolute simplicity prevails the action, without requiring any further information.

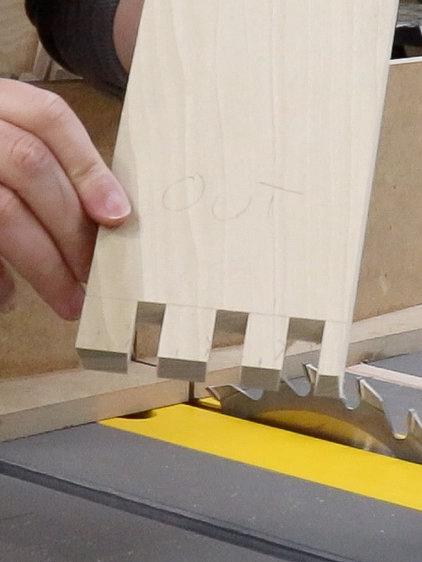

8. Cheapest Wooden Wire Stripper

Spending 20 minutes will prepare the cheapest machine for wire stripping. You just have to make some precisely measured cuts on some leftover wooden pieces.

There’s basically no adjustment or irritating attachments, only matching the specs. And the entire process stands within a single dollar with common equipment.

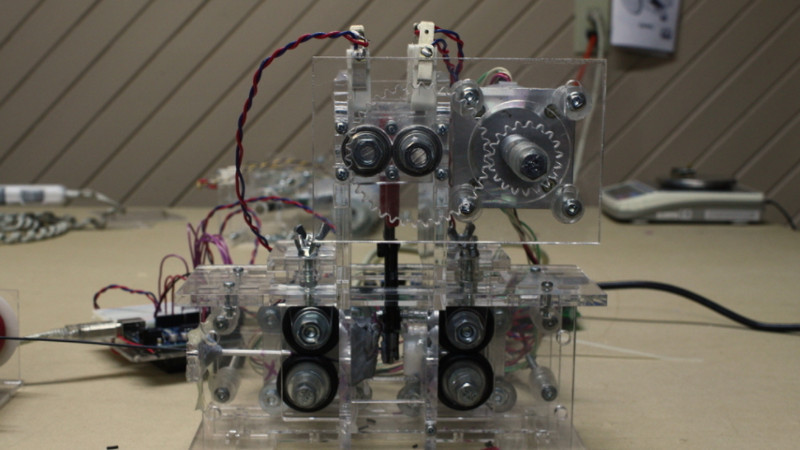

9. Automated Stripping Machine

Practical design on real-life action definitely saves your hassle on the job. And you can save some precious working time with an automated mechanical gear. The chosen tutorial intentionally utilizes breadboards to ease the task on electronics.

Likewise, the project possesses certain challenges for any daring DIYer. The explanation comes from a video demonstration, integrated right at the end.

Fewer introductory words should immediately encourage you to go for the video. All the steps get captured from a close, clean & convenient angle. Obviously, the complete implementation adds up the cost, definitely not exceeding your limit.

10. Commercial-Grade Stripping Tool

Busy garage or workshop eventually gets overwhelmed with a wired mess. And a simple stripper can barely handle the intensity of stripping different sized wires.

Raising the budget, you can use the video tutorial to create a metal stripper right at home. You just have to drill some holes to install different sized nut bolts.

Unless you know Spanish, you can ignore the background commentary. But you have nothing to lose, the entire demonstration is reasonably self-explanatory.

Conclusion

As discussed, you can get yourself toy-like tools up to commercial designs. It’s essential for you to realize your resources, available time & amount of wire. Right there, you can easily figure out the most satisfying project to meet your demands.

Ask Me Anything