A reciprocating saw is one of the most useful tools for remodelers, electricians, plumbers, and DIY enthusiasts. The versatility and convenience of reciprocating saws suit different projects hence the popularity. It is a motorized backsaw for easy and quick cutting of different materials.

A reciprocating saw is useful for cutting wood, drywall, studs, pipes, and other materials that most saws cannot cut through. Like any other power tool, you need to understand how it works to make the most use out of it.

If you just owned your first reciprocating saw or thinking about getting one, this article is a great resource. I have explained how it works, how to use it, and several tips to help you when using one.

Table of Contents

What are the parts of a Reciprocating Saw?

Here are the parts of a reciprocating saw that you need to understand.

- Blade: Different types of saw blades can be used to cut different materials, such as wood, PVC, metal.

- Shoe: This is the part of a reciprocating saw that you actually guide across the piece of wood that you’re cutting. It helps to control the blade’s angle and keeps your reciprocating firmly on the wood.

- Rear Handle: This is the part to hold when pushing the saw forward to cut.

- Front Grip: It is a secondary handle for your other hand. It helps to guide the saw along the cutting line.

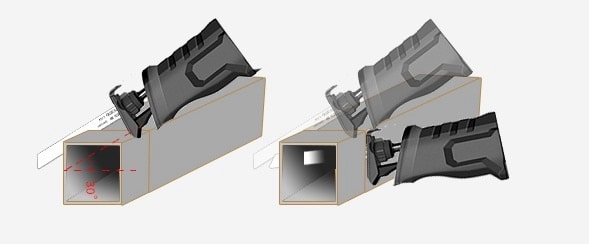

- Blade Clamp: Reciprocating saws that require tools to change the blade will usually have a blade clamp assembly to securely hold the blade. To change a blade on a reciprocating saw with a blade clamp, first, you need to loosen or remove a set screw using a screwdriver or an Allen wrench. This releases the blade clamp, along with the blade, so you can remove them from the reciprocating shaft. To install a new blade, insert the blade shank from the front between the reciprocating shaft and the blade clamp, put the set screw back in the hole and retighten securely.

- Vents: Ensure that the reciprocating saw effectively dissipates heat during operation to avoid shutdown due to excessive internal temperature.

- Handle Rotation: Open the switch to adjust the handle Angle to adapt to different working conditions.

- Carbon Brush: The brush is made out of a durable carbon alloy, has a lead wire and spring attached to it, and its primary purpose is to conduct electrical current from the stationary wires to the moving parts of your tool. Brushes are one of the most commonly replaced power tool parts because carbon brushes are wear items, meaning that through friction and use they will gradually wear away until they need replacing. Worn brushes are a common cause of intermittent motor function, reduced electric braking, and reduced motor power. A worn-out brush will often be worn down near to the wire lead and can be cracked, pitted, or burned.

- Trigger: Pressing the trigger switch turns the reciprocating saw on, and releasing it turns the tool off. Aside from turning on the tool, the trigger switch also acts as variable speed control for the tool – the deeper you press it inward, the faster the tool runs, up to the limit set by the speed range selector.

- Trigger Lock: The lock-on button is usually located just above the trigger switch. Pressing this button lets you run the reciprocating saw at its current speed even if you let go of the trigger switch, which can be handy for longer cuts or for cuts that require consistent speed.

How Does a Reciprocating Saw Work?

The saw has a design that incorporates a blade that moves back and forth on the rapid motion. For practical use, you should hold it with both hands. It is designed to cut a variety of materials and allows you to cut an angle to suit the nature of your project.

The versatility of this powerful tool allows you to cut through metal, PVC, drywall, plywood, etc. It works with different blades for the specific material you intend to cut. This means the blade is removable and replaceable.

Note:

- Use a wood cutting blade for regular plywood pieces and lightweight wood planks.

- Use a metal-cutting blade for pipes and solid metal pieces.

- Use a wood and nail blade for cutting studs or any roofing material with nails.

- A pruning blade works well if you intend to cut tree branches.

Where to Use a Reciprocating Saw

If you are debating whether a reciprocating saw is right for you or not, it is essential to understand where to use it. A reciprocating saw cuts materials in places where a large handsaw cannot fit. It is shorter, easy to maneuver, and reaches limited-space areas.

Additionally, it acts quickly using a push and pull mechanism to cut. It takes less effort of you as long as you set it correctly. It is particularly useful for do-it-yourself projects.

You can use it when installing an outlet, fitting a window, or changing PVC piping. It also works well for cutting through nails and screws. Like other saws, a reciprocating saw can process smaller logs and wood pieces.

- Wood cutting.

- Metal cutting.

- Outdoor Pruning.

- Plastic Cutting.

Step By Step Procedure of Using A Reciprocating Saw

- Choosing The Blade And Installation

It is important to unplug the cord of the saw before installing the blade. If you have a wireless saw, remove the battery pack to prevent any injury when fixing the blade. Ensure you have the right blade for the specific material you intend to cut.

In most cases, the blades have information on the side regarding the materials it cuts. If yours does not list that, follow the guideline highlighted above.

A simple way to select the right blade is to ensure it is 2 to3 inches longer than the thickness of the material. That way, the blade has enough room to move back and forth.

Press the lever or button on the chuck. The chuck is the cylindrical metallic piece at the end of the saw. It is the part that holds the saw and has a button, usually black or red. Pressing it down, unlocks the chuck, and opens it up to insert the blade.

Once the blade is in place, release the lever to secure it completely. At this stage, ensure the teeth of the blade are facing toward the handle. You can then adjust the show to ensure the blade is stable and long enough.

- Prep The Work Surface

Prep the material you are cutting by drawing a line to mark the cutline. You can use a marker or pencil for this or a straightedge as a guide. Next, clamp the material on the worktable to secure it in place.

If the material shifts when you push it, use another clamp for extra security. If the material is super small, you can skip this stage and lay it on the edge of your work surface.

Use protective equipment such as safety glasses and earplugs. The cutting process usually produces dust and debris that could enter your eyes. Also, the back and forth cutting motion can be noisy, especially with dense, thick materials.

Hold the reciprocating saw with both hands and ensure you have an excellent grip. If you are right-handed, hold the handle with your right hand and use the other hand to support behind the chuck. Ensure your finger is off the trigger until you are ready to cut.

- Setting the Saw

Set the blade such that it lies at the end of the line you marked. This step ensures the shoe sits flat against the material you are cutting. Exert pressure to the shoe to ensure the saw does not kick back while cutting.

It is crucial to ensure the blade does not touch the material yet. If it does, it might not deliver a clean, straight cut once you start running the saw. In a situation where you are cutting a round object, press it as much as you can to prevent slipping when you begin.

Use the index finger of your dominant hand to squeeze the trigger lightly. This action will move the blade back and forth. Keep pressing the trigger until the saw reaches its maximum speed. At this stage, make sure the saw is stable in your hands for a quality cut.

Some people prefer working with the saw upside down. In such a case, you can use the middle or ring finger to press the trigger.

Some designs of reciprocating saws have variable speeds. This feature allows you to adjust the speed according to the material you are cutting.

For example, if you are cutting wood or drywall, the faster setting works best. For hard materials such as metal, a slow setting is ideal and prevents breaking the blade.

- Cutting Through The Material

Once the blade is running on the right speed, keep the shoe firm against the material, so the blade lies perpendicular to it. Push the blade slowly along the line without exerting any force toward the material. Let the blade to cut through but guide it to ensure it cuts straight and on the marked line.

After cutting through the entire piece, release the trigger before you pull the saw out. This will prevent the material from kicking back. You can change the angle of the blade as you cut to reduce the surface area and cut faster.

When making plunge cuts, set the shoe against the material to ensure the blade is parallel to the surface you are cutting. You should then pull the trigger and tilt the saw to cut at a 30 to 45-degree angle.

Keep tilting the saw until it is perpendicular to the material, and the blade is through to the other side. A plunge cut is ideal for cutting holes in drywall or large panels. It is essential to take caution and ensure there are no wires or pipes behind walls when making plunge cuts.

Tips for rapid wood cutting

Tips for rapid metal cutting

- Winding-up

When you finish cutting the material, press the button on the side to remove the battery pack. If you have a corded saw, unplug from the power outlet. Keep the saw on its side to ensure the blade is parallel to the ground. This position will prevent it from bending or breaking from the weight of the saw.

Video tutorial on the steps to follow when using a reciprocating saw

Here is a simple guide that you can follow to use a reciprocating saw and achieve a clean cut. This video explains the process in detail.

Safety Tips When Cutting With a Reciprocating Saw

Reciprocating saws are restively safe; however, like other power tools, it is vital to take caution when using it. These tips can help you use your saw better and prevent further damage to materials and the surrounding.

- When cutting into walls and floors, you should be careful not to cut through underlying pipes, electrical wires, and heating vents. If you are not sure if there are any, consider assessing the situation first.

- Always ensure the power is not on when changing blades.

- Do not skip protective equipment regardless of the material you are cutting.

- Reciprocating saws can kickback, especially when the blade pulls out of a cut. Keep this in mind when working on ladders to avoid unforeseen accidents.

- It is easy for the blade to buck when cutting through wood and pipes. Be careful when cutting materials that do not have support underneath.

- Avoid touching the blade after use as the back, and forth motion tends to generate a lot of heat. Also, leave it for some time before changing it or storing the saw.

A reciprocating saw comes in handy for plenty of cutting needs. Depending on the type of your project, this saw can help cut in tough-to-reach areas. It is a handy tool and applies to cut different materials, of course, with the right blade.

This guide can be a great starting point if you are looking to learn how a reciprocating saw works. It has tips, a step-by-step guide on how to use one and safety precautions you should keep in mind. If you have any queries, feel free to drop a comment and let’s interact.

Ask Me Anything