A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. This process is called casting. By creating your own DIY foundry, you will be able to save money on casting by casting at home. It’s very easy and affordable. In this article, we shall discuss the items required and the steps to create a homemade foundry.

The following instructions on how to make a DIY foundry are intended for the homesteader, the farmer, and anyone who might be interested in melting down scrap metal. I think that having a foundry at home is both fun and exciting. Are you ready to build? Let’s get on with it then.

Table of Contents

1. DIY Foundry

Do you have many aluminum cans around, and you don't know what to do about them? Well, here is an Idea that can help turn your can't into something else; a DIY foundry! A foundry will help melt all the cans into a single element. This foundry is made from a metal bucket, stainless steel bars, metal pipe, coffee pot, castable refractory, and bolts. instructables

2. DIY Mini Metal Foundry

Do you have $20? Do you need some aluminum that needs casting? If yes, then you need this mini metal foundry! The foundry uses a metal bucket, but the bucket was coated with a thick layer of sand and plaster of Paris mixed thoroughly with water. To create the burning space, once you fill the metal bucket with the mixture of sand and plaster, fill a bowl with water and keep it at the center of the mix. Once the mixture is dried, remove the bowl, and you're good to go. instructables

3. DIY Foundry Upgrade

You don't have refractory concrete/ cement if you don't have to worry. You can make a functional metal foundry with cement, perlite, and other materials listed in this guide. The most expensive and practical part of a foundry is the insulation. The insulation allows the foundry to resist more heat, making it more efficient. instructables

4. Homemade Metal Foundry

If you're still doubting that you can melt/cast aluminum, metals, and can by yourself, here is an excellent idea of a metal foundry that can help with the casting. However, the foundry quickly moves with the caster wheel attached to the bottom. You can carry it anywhere you like. vegoilguy

5. Ultimate Foundry DIY

The primary source of insulation for this foundry is insulated fire bricks. It has a low density, and it doesn't allow air to get through to it, thereby having a low conductivity. Cut the bricks into pieces and use them to line the walls and bottom of the steel bucket. After this, you can continue with the build.

6. How To Make A Foundry

This foundry is made from an aluminum gallon. Cut off the top of the gallon and the middle part. Now discard the central part leaving only the top and the bottom. After that, mix refractory cement with perlite and line the gallon wall.

7. Metal Foundry With Gas Cylinder

Always ensure that the gas cylinder you're using is empty; if you notice substance in it, carefully evacuate all the gas and clean it accordingly. Now, cut the top of the cylinder and drill one hole on the center of the top. Drill another hole by the side of the cylinder as the air passage.

8. DIY Foundry Build

The most difficult. And the time-consuming part of a foundry uses the insulation step, and you need to be careful of the type of material you use. In this video guide, they modify an insulation system from natural materials. Check the link below to know more about the insulation.

9. How To Build A Foundry

The first part of a forge is the furnace body! This part needs to be taken care of with a lot of attention because if the furnace body is not well-packed with the required materials and insulation, the foundry might not be so efficient. The insulation used for this is 5.1 cm ceramic fiber wood. wikihow

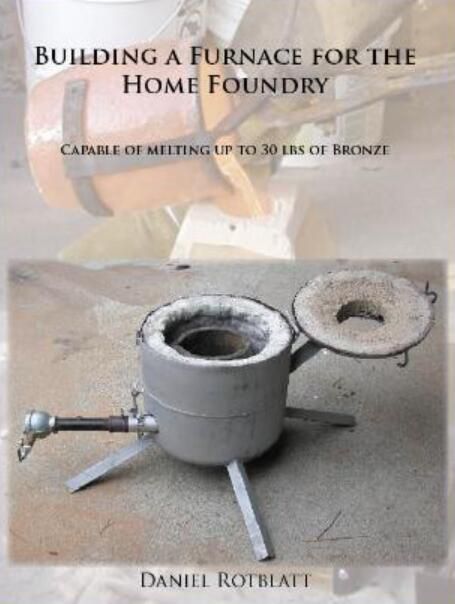

10. DIY Foundry

This foundry is capable of melting 25lbs of bronze in 30 minutes! Its maximum capacity is 30lbs of bronze or 10lbs of aluminum. This is quite fantastic equipment. The burner needs to come at an angle to ensure the foundry is as efficient as the one described in this guide. rotblattsculpture

11. DIY Aluminum Foundry

Furnace cement will work better for this foundry because it has some silicates. This will make the furnace body strong. Other materials and supplies required include shop vac, stainless steel pipe, paint can, welding gloves, and stainless steel stockpot. instructables

12. How To Make A Foundry

Beginners shouldn't work with a gas bottle. However, if you can exercise the required attention and patience, you will get your work done quickly. One important measure that needs to take place before you use the gas tank is to empty the tank, take off the valve and fill the tank with water. Then, leave the rank for a while. instructables

13. DIY Electric Aluminum Foundry

This electric aluminum foundry is built mainly with insulating fire bricks. The whole body and lid of the foundry are made by joining fire bricks into a container. Once you have the fire brick container, you can use a metal plate to cover the top and the bottom. Then, support the walks with metal square tubing at every joint. The gear source uses a burner removed from an electric cooker.

14. Cheap Mini Foundry

Get a steel bucket, perlite, plaster of Paris, and sand for this cheap mini foundry. Then, mix the plaster of Paris, perlite, and sand in the steel bucket with 1.3 parts water. Once you have the mixture, deep a bowl in the center and add weight to it to sit deep. Once the mixture is dried, remove the bow, and you're good to go.

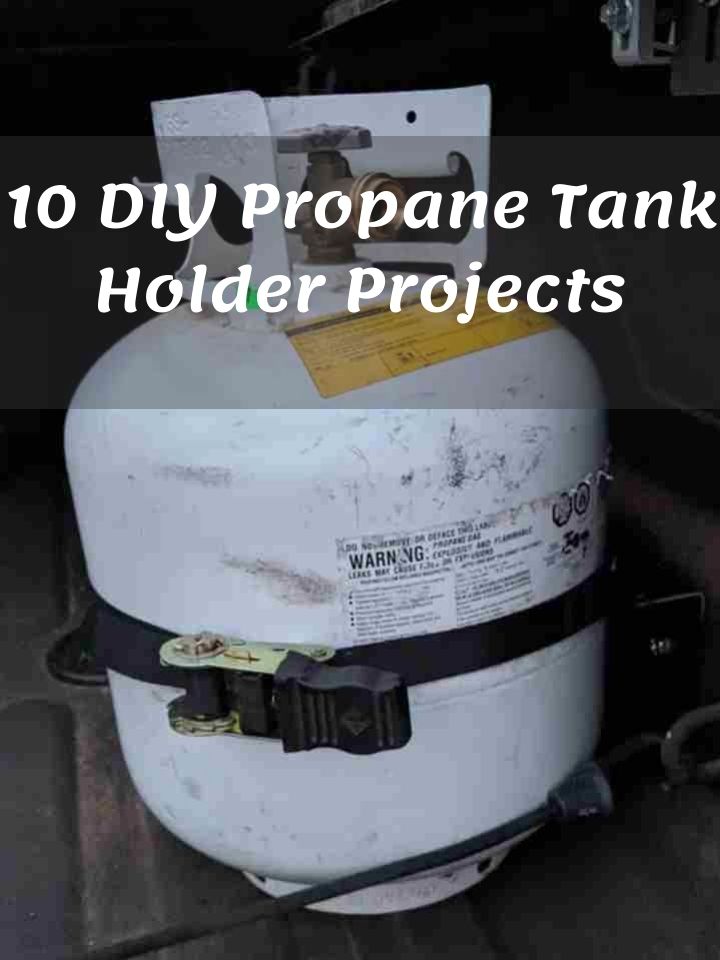

15. How To Build Foundry With Propane Tank

You don't want to cut into a propane tank you found immediately without checking if it's empty. To confirm the emptiness, open the tank for a while and let all the gas come out. After this, remove the whole valve from the tank, and if you're smelling propane, it is good to pour water into the tank to completely get all the propane out. After this, you can start cutting.

16. DIY Metal Foundry

Here is a great plan to show you how to turn your old gas tank into a foundry with some unique and straightforward steps. You will need other materials alongside the tank, such as plaster cement, water, a narrow container, a bucket, and other materials used in this guide.

17. Aluminum Casting Foundry

Colton wool is an excellent insulation product, but the primary insulation system used for this foundry is fire clay and sand. The size of the gas cylinder used is 13kg. Other materials necessary include screws, hoses, nuts, and bolts. instructables

18. Chimenea Foundry DIY

If you're using a chiminea for your foundry, that means you will need a crucible to go with it. Set the crucible at the center and put the soda can inside. Now, gather wood or charcoal inside the chiminea. Put the fire start and plug the blow dryer. With this, you have your foundry. instructables

19. DIY Solar Foundry

Here is an excellent plan on setting up a solar foundry; the system seems complicated, but it was terrific. The tracker works when the sun is out and the melting surface is adjusted to the focal point. However, it would be best to be careful and always wear protective goggles.

20. Homemade Propane Foundry

One thing that makes this homemade propane foundry stand out is its ability to move. It has a four-wheel cart that carries it around; this makes it easy for anyone to move it. Check out the design from the link below.

21. Micro Metal Foundry

If you already have a foundry, you can add this modification to make it stand out. It is a micro desktop metal foundry! All you need for this is a mini/small aluminum bucket, sand, perlite, and a small container for molding.

22. Homemade Foundry Build

The materials needed for this homemade foundry include a stainless steel drum, a plastic bucket, sand, concrete, plaster of Paris, metal pipe, water, and shovel. The first thing you need to do is cut a hole for the air passage at the bottom of the drum.

23. DIY Foundry

The Main air source for this foundry is the hairdryer! It is an efficient air source; once you have a proper connection and have it plugged, you're good to go. The fire source is charcoal.

24. How To Make Wood Fire Foundry

While molding the wall of this foundry, it is better to cover one end of the PVC pipe that will go into the cement mixture with plaster so that it will have the ability to hold water. The purpose of the water is to ensure there is enough weight in the pipe to press down the mixture. You can apply a verse line to the pipe to allow easy removal.

25. DIY Benchtop Foundry

Here is a mini/benchtop foundry made from materials you can find around. The idea is impressive and creative; however, care needs to be taken while working because of the open fire/heat. instructables

Conclusion

It is never a bad idea to see something creative and unique and decide to try it out! You've gone through the guides above and seen how you can easily make a foundry by yourself with little practical cost or no cost at all. You can always read further on the idea you want by clicking any of the links below each idea. This is the time! Do it Yourself!

Ask Me Anything